| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : longkuang

Model Number : 0.05-3.0mm

Place of Origin : China

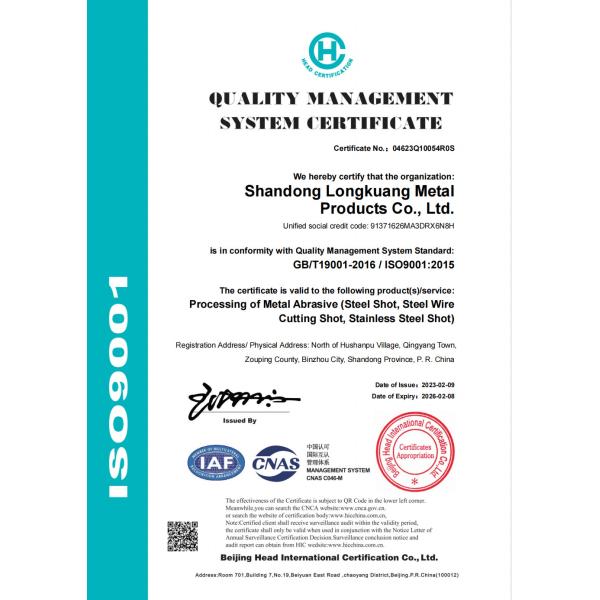

Certification : GB/T19001-2016/ISO9001:2015

MOQ : 1000kg

Price : negoitable

Packaging Details : Ton bag: wooden box, wooden pallet, barrel

Delivery Time : Determine based on tonnage and specification model

Payment Terms : L/C T/T ...

Supply Ability : 50000ton/year

Density : 7.4 G/cm3

Owen's lifespan : 2000-2800times

Hardness : 40-60 HRC

Durability : Long-lasting

Adapt to process range : Surface Pretreatment Before Spraying; Casting Sand Cleaning; Pipeline Descaling, Etc.

Impact Resistance : High

Size : 0.05-3.0mm

Surface Quality : Smooth And Clean

Affordable Cast Steel Shot S390 for Cost-Effective Surface Cleaning

Cast Steel Shot, also referred to as Steel Shot, Steel Abrasives, projectiles, alloy steel shots, steel particles, and steel shots, is commonly known as shot blasting abrasives, shot blasting machine abrasives, blasting shot materials, shot blasting and rust removal abrasives, blasting materials, shot blasting abrasives, sandblasting abrasives, sandblasting consumables, sandblasting machine abrasives, shot blasting and rust removal abrasives, and shot blasting is ideal for shot blasting cleaning, shot peening strengthened metal abrasives, among others.

Cast steel shot serves as a substitute for cast iron shot and iron shot. It finds application in drum-type, chain-type, hook-type, crawler-type, through-type, turntable-type, accumulation-type, step-by-step, trolley-type shot blasting machines, blasting machines, etc. It is used in shot cleaning machines, shot blasting equipment, shot blasting machines, shot blasting, shot blasting equipment, sandblasting machines, sandblasting equipment, and metal abrasives in steel pretreatment production lines, steel plate pretreatment production lines, and steel structure pretreatment production lines.

Types of cast steel shot:

(1) Steel Shot

Steel shot typically has a hardness of HRC40-50. When processing hard metals, the hardness can be increased to HRC57-62. They possess good toughness and have a service life several times longer than that of cast iron shots. They are extensively utilized.

(2) Cast Iron Shots

Cast iron shots have a hardness of HRC58-65. They are highly brittle, prone to breakage, and have a shorter lifespan. They are not widely used and mainly employed in applications requiring high shot peening intensity.

Our company primarily supplies the aforementioned two types of cast steel shot.

a: Exceptional Performance:

b: Superior Surface Treatment:

By employing cast steel shot, users experience exceptional performance and remarkable surface treatment results, making it the preferred choice for shot blasting applications, rust removal, and strengthening metal surfaces.

Adaptable Process Range:

Diverse Applications:

Effective Rust Removal:

Strengthening Capabilities:

Surface Treatment:

Pretreatment Applications:

With its wide range of applications and effectiveness across different processes, cast steel shot proves to be a versatile and reliable choice for surface treatment, cleaning, rust removal, strengthening, and pretreatment requirements in various industries.

Inner packaging: 25kg/bag with inner film bag.

Outer packaging: nylon woven bag, kraft paper bag, carton.

Whole ton packaging: pallet or ton bag.

|

|

High Impact Resistance Steel Shot And Grit S390 For Surface Cleaning Images |