| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : longkuang

Model Number : 0.8mm 1.0mm 1.5mm 2.0mm 2.5mm

Place of Origin : China

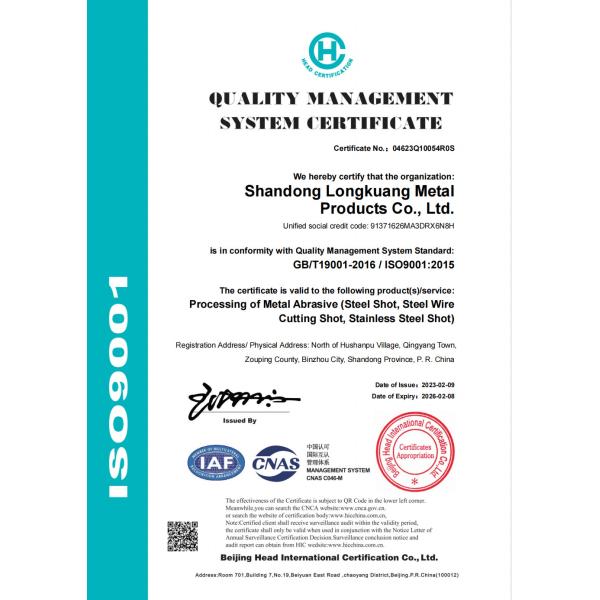

Certification : GB/T19001-2016/ISO9001:2015

MOQ : 1000kg

Price : negoitable

Packaging Details : Ton bag: wooden box, wooden pallet, barrel

Delivery Time : Determine based on tonnage and specification model

Payment Terms : L/C T/T

Supply Ability : 50000ton/year

minimum density : 7.8g/cm3

tensile strength : 1.0mm:1750~2150 Mpa 1.5mm:1250~1450 Mpa

chemical composition : C 0.45~0.75% Mn 0.40~1.20% Si 0.10~0.30% S<0.04% P<0.04%

application : Shot Blasting, Shot Blasting, Die Casting Cleaning, Casting Shot Blasting, Etc.

Size : 0.8mm 1.0mm 1.5mm 2.0mm 2.5mm

Hardness deviation : The Maximum Deviation Range Is ±1.0HRC Or ±40HV

average hardness : 1.0mm:51~53 HRC(525~561HV) 1.5mm:41~45 HRC(388~436HV)

Name : Steel Wire Cut Pills

Shot Blasting Steel wire cut pills with C 0.45~0.75% Mn 0.40~1.20% Si 0.10~0.30% S<0.04% P<0.04%

Enhanced surface finish: Steel cut wire shot can be manufactured with specialized surface treatments or coatings that enhance the surface finish of the workpiece. These treatments can result in smoother, more polished surfaces, reducing the need for additional finishing steps and improving the overall aesthetic appeal of the workpiece.

Customizable hardness range: Manufacturers can offer steel cut wire shot with a wider range of hardness options, allowing for customization based on specific cleaning requirements. This flexibility enables users to select the optimal hardness level for different materials and surface conditions, ensuring efficient and effective cleaning while minimizing the risk of surface damage.

Reduced dust and debris contamination: Steel cut wire shot can undergo additional processing or surface treatments to reduce dust and debris generation during the shot blasting process. This minimizes the risk of contamination, particularly in applications where cleanliness is critical, such as in the semiconductor or medical device industries.

Improved impact energy transfer: Steel cut wire shot can be engineered to optimize the transfer of impact energy to the workpiece surface. This improves the cleaning efficiency and ensures a more thorough removal of contaminants, resulting in shorter cleaning cycles and increased productivity.

Anti-clogging properties: Steel cut wire shot can be designed with features that reduce the likelihood of clogging or clumping during the shot blasting process. This ensures a consistent flow of shot particles and maintains cleaning performance over extended periods, reducing downtime for maintenance and improving operational efficiency.

Enhanced recyclability and cost-effectiveness: Manufacturers can develop steel cut wire shot with improved recyclability, allowing for more efficient recovery and reuse of the shot particles. This not only reduces waste and environmental impact but also lowers the overall cost of the shot blasting process.

Specialized application focus: Steel cut wire shot can be tailored to meet the specific requirements of certain applications or industries. This includes developing shot particles with characteristics optimized for specific materials, surface conditions, or cleaning challenges, ensuring the highest level of performance and effectiveness in those particular applications.

| Technical Parameters | Values |

|---|---|

| Tensile Strength |

|

| Chemical Composition |

|

| Average Hardness |

|

| Production Process |

|

| Hardness Deviation | The Maximum Deviation Range Is ±1.0HRC Or ±40HV |

| Application |

|

| Name | Steel Wire Cut Pills |

| Minimum Density | 7.8g/cm3 |

| Size |

|

| Microstructure |

|

Inner packaging: 25kg/bag with inner film bag.

Outer packaging: nylon woven bag, kraft paper bag, carton.

Whole ton packaging: pallet or ton bag.

|

|

0.8mm 1.0mm 1.5mm Steel Cut Wire Shot Rounded Low Carbon Shot Blasting Abrasives Images |